Die-Casting

Die-Casting

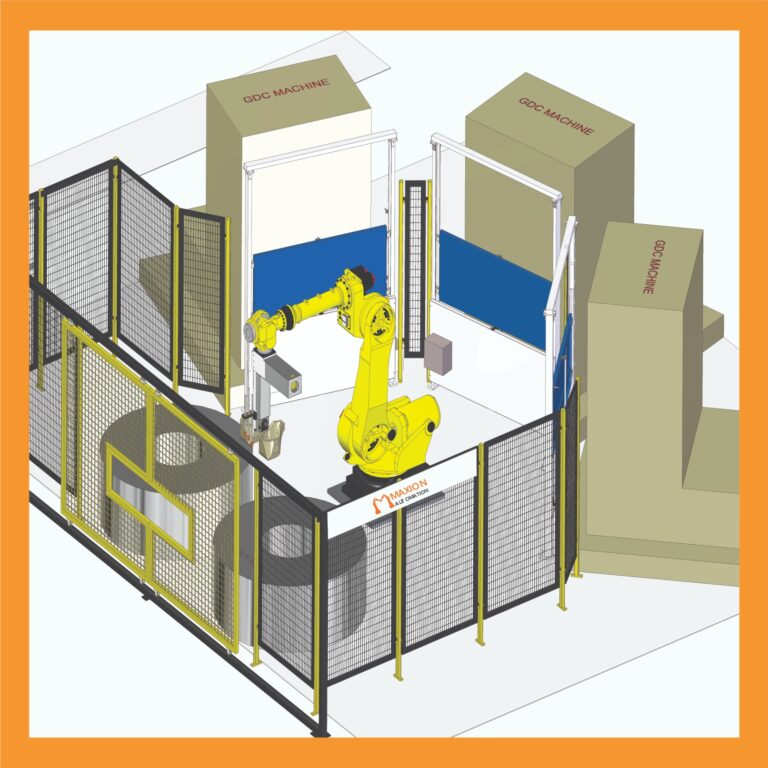

Maxion Automation automate pre casting and post casting processes helping in safe working for human thereby deliver increase in production with quality assurence. Die-Casting Solutions:

- High-Pressure Die-Casting Extraction

- GDC Molten Metal Ladling / Metal Pouring.

- Runner & Gate Cutting

- Casting Deflashing, Deburring

- Trimming, Quenching

- Auto Extractor

- Auto Sprayer

- Servo Auto Sprayer

- Cooling Conveyor

Quality work

Our Products

Robotic Metal Pouring

Pouring molten metal takes a steady hand, and nothing is more stable than a robot. Optimized to deliver the same quantity every time, a foundry robot skims dross and ladles metal more steadily than any human, which eliminates turbulence and spills.

Robotic HPDC Extraction

To utilize the robot to its maximum potential by combining the extract process with additional tasks such as insert loading, spraying,ing or handling the casting through the cooling and trimming operations. Peripheral equipment including cooling racks, trim presses, conveyors, and safety fence can all be provided by Maxion Automation

Alluminium Deflashing

Maxion Automation offer the quality of castings needs to be good and the parting line flash thickness and length should be consistent. If there is consistency, robotic deburring can drastic -ally improve the productivity and significantly reduce the dependence on labour. Inventory costs will also come down as the components can be delivered to customers faster.

Robotic Spraying

Robotic spraying systems with shelf-mounted robots designed especially for operation on die-casting machines, even very large machines can be automated. The product range covers payloads from 16 to 270 kg and reaches up to 3,900 mm. The foundation for process reliability and high performance during robot-based metal casting

AUTO EXTRACTOR

Auto Extractor can be used with DieCasting Machine to extract casting from Die Casting Machine. Multi bar linkage arm is adopted for Strong bearing capacity. Vertical as well as Horizontal ajustment can be done to match height of component at DCM. It can be operated independently or connected to diecasting machine & run automatically.

AUTO SPRAYER

Auto spraying for fix & Movable mould can be done separately. spray volume can be adjusted as required. Spray programmes can be define in system according to requirements programme Receipe cab be selected from HMI for dufferent moulds. nozzles adopt the bladder control method, to precisely control the flow to meet the spray requirements of different die at different place

SERVO AUTO SPRAYER

Servo Auto Sprayer driven by servo motor working stably & precisely. Auto spraying for fix & Movable mould can be doneIt is suitable for 450 Ton to 900 Ton die-casting machine. spray volume can be adjusted as required. Spray programmes can be define in system according to requirements. programme Receipe cab be selected from HMI for dufferent moulds. x Axis & Y Axis can be stop at any point.

COOLING CONVEYOR

Extracted casting transfer through cooling fans to cool casting. Height can be adjusted as per requirement. Induction motor with drive & metallic chain arrangement added.