Fabrication,Body-in-White & Arc Welding

Fabrication,Body-in-White & Arc Welding

Maxion Automation design process for BIW line also manufacture fixtures and take care of rest of the integration part to improve production efficiency.

Welding Solutions:

- BIW Fixture Design and Process Finalization

- Robotic transfer Line for Spot welding

- MIG/ CO2 Robotic / SPM Welding

Quality work

Our Products

BIW / SPOT Welding

Robotic Spot welding is commonly used technique in the automotive, aerospace, and electronic industries. Spot welding with a robot involve using a robotic arm equipped with welding gun to joint two metal part. Maxion automation will do process, design, manufacturing of BIW line with install -ation & commissioning of whole line.

MIG/ CO2 ROBOTIC Welding

Ability to perform complex welding on chassis or child parts mating together with arc welding. advantages of MIG Co2 welding with a robot include increase productivity, improved consistency and quality, reduce labour costs. the use of Co2 Argon gas as a shielding gas allows for a more stable and controllable welding arc, resulting high-quality weld.

JIG & FIXTURE Manufacturing

Jig and fixture manufacturing is a crucial process in the manufacturing industry. By designing and producing specialized tools, manufacturer can ensure accurecy, consistency, and repeatability in manufacturing process leading to higher quality products and increased efficiency.

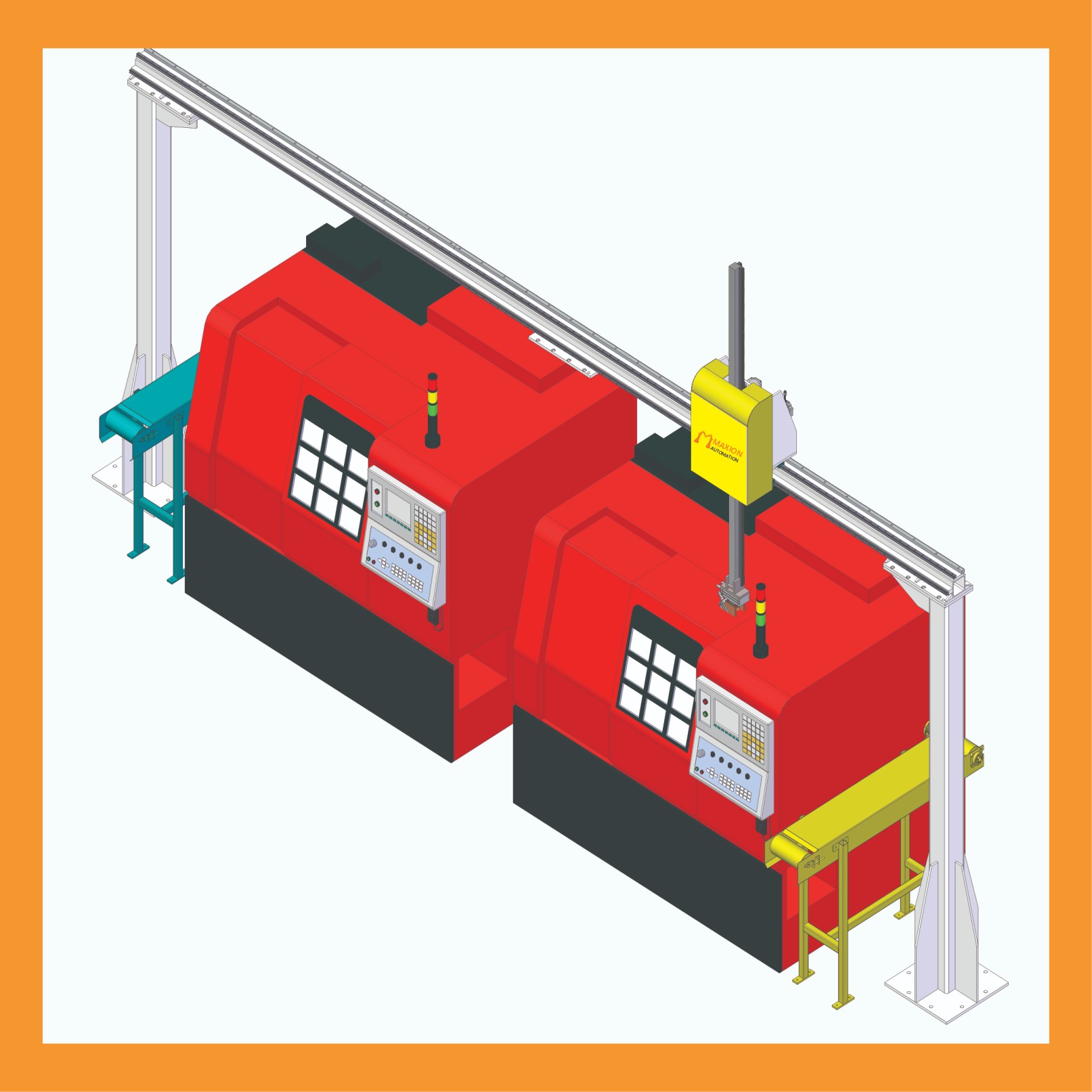

SERVO GANTRY

Servo gantries are used in various manufacturing and material handling applications, such as pick-and-place operations, assembly, and material transfer. They are highly versatile and can be customized to meet specific application requirements. The servo-controlled linear axes allow for precise control of the gantry's movement, making them ideal for applications that require high accuracy and repeatability.