Stamping

Stamping

Maxion Automation automate Stamping Press with robotic as well as with gantry system for parts transfer, modern stamping workshops are usually equipped with stamping robotic arms to improve production efficiency and complete difficult or dangerous work for workers.

Stamping Solutions:

- Gantry System for Press Handling

- Robotic transfer Tandem Line.

- Mechanical Manipulators

Quality work

Our Products

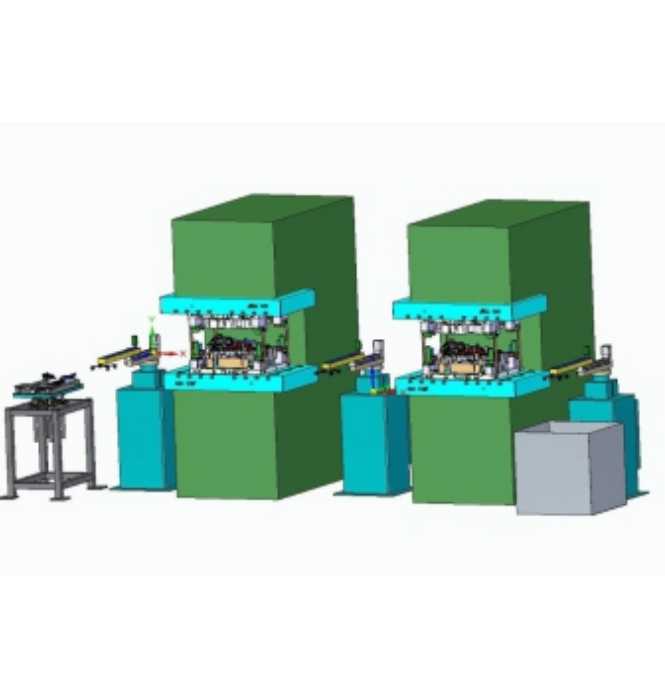

Press Tandem Line

Robotic system can be used in press tandem line for several task, such as handling, part transfer, and quality inspection. Robotic systems in press tandem line offers several benifites, including increase in production speed, improved quality control, reduce waste and improve worker safety.

Press Gantry

A Gantry system is type of robotic system having stationary arm & moving bridge, that spans distance between the two sides of frame. In small press automation, a gantry system can be used to move parts in and out of a press, as well as to position parts for processing. Advantages of gatry to increase stroke per minute & safety to operator.

Press Centring Tending

In a Robotic press tending, part centering and destaking several factors should be considered. vaccume gripping commonly used to gripe sheet metal parts. selecting the right robot for press tending, part centering and destaking can greatly improve the efficiency and accurecy of manfacturing process, results in higher production.

Press Handling Manipulators

Manipulators commonly used for part handling in small press applications. including electric, hydraulic manipulators. Electric/ Servo manipulator used gear & motor for lifting tilting to transfer part from one press to another.