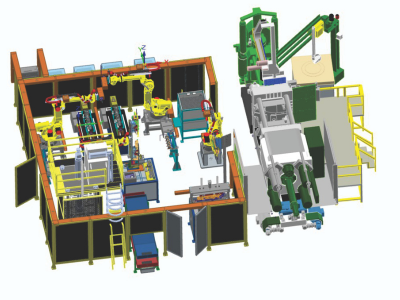

Robotic HPDC Extraction

Maxion Automation Pvt Ltd delivers customized automation solutions to boost efficiency across industries, backed by expert knowledge and dedicated customer support.

We work with globally renowned brands to bring you the latest

advancements in factory

automation. Our solutions leverage modern, state-of-the-art tools that

enable you to stay ahead of

the competition.

With deep experience across diverse industries, our team understands the unique challenges businesses face. This expertise allows us to deliver customized solutions that address your operational goals effectively and efficiently.

We believe that every business deserves a solution as unique as its needs. By combining proven industry practices with innovative thinking, we craft automation systems that optimize performance and deliver measurable results.

Our journey with you doesn’t end with delivery. From consultation and design to seamless installation, training, and maintenance, we provide support at every step. We’re committed to ensuring your long-term success.

Quality is at the heart of what we do. Every solution we deliver adheres

to global standards,

ensuring it is robust, reliable, and built to withstand the demands of

modern industry.

In today's world, sustainable practices are not an option but a necessity. We prioritize energy efficient and eco-friendly automation systems, helping you reduce costs while making a positive impact on the environment.

At Maxion Automation, we are dedicated to delivering excellence through precision-engineered solutions that adhere to global standards and rigorous quality assurance. Leveraging our deep expertise and partnerships with leading brands, we create advanced, reliable, and future-ready automation systems that deliver measurable results. Renowned for innovation and quality, we craft solutions that adapt to evolving client needs, enhance performance, and drive success. Our unwavering commitment to customer satisfaction ensures every product and service exceeds expectations, empowering businesses to achieve their goals.

Connect with us to discover how we can elevate your operational success with precision and innovation.